Drilling

Medical Moulded Products: Cleanroom Standards · Drilling of Plastic Mouldings · Talk to us today

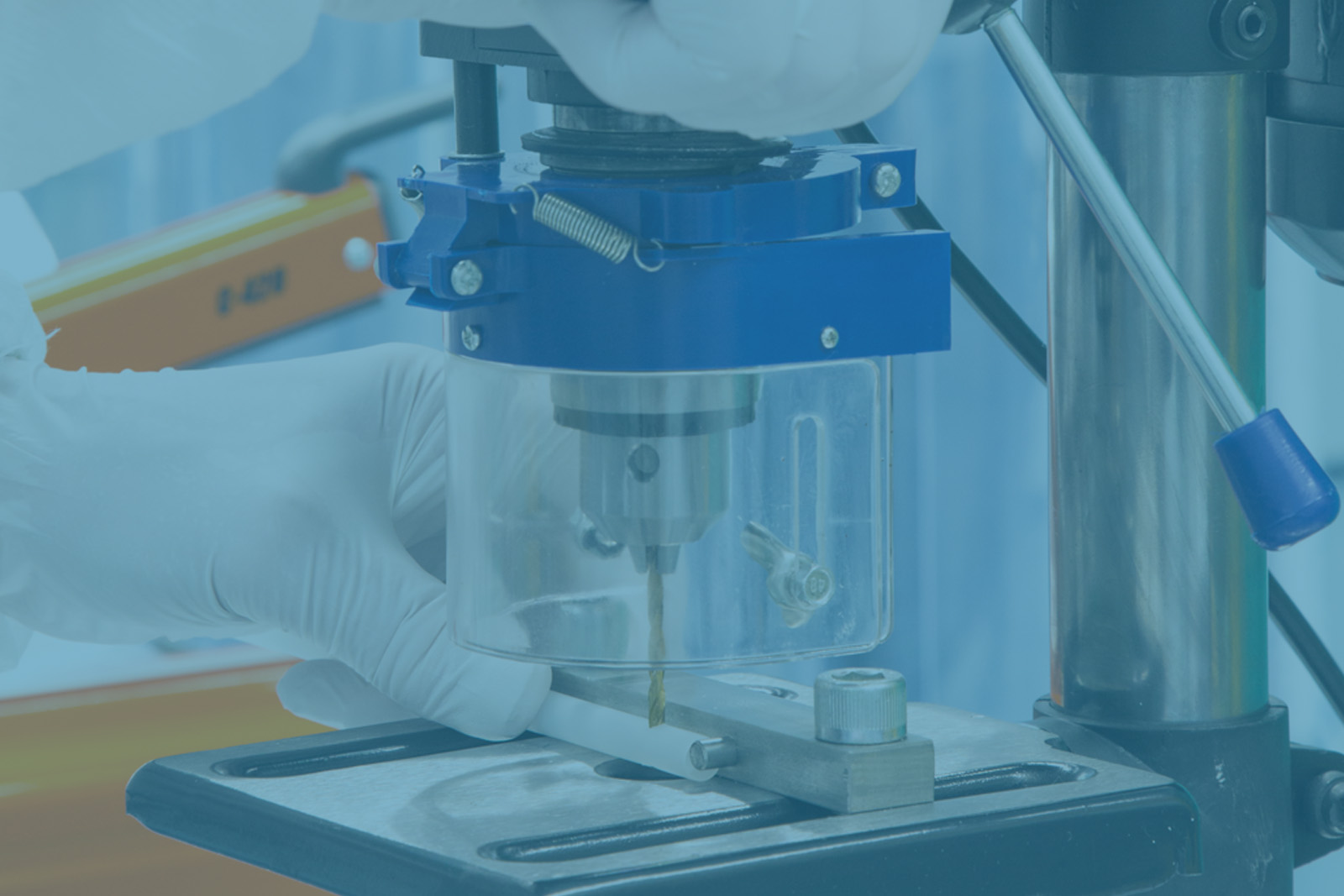

Drilling

Drilling of plastic mouldings can be carried out as a secondary operation for the following reasons:

To produce a hole that cannot be produced within the mould tooling.

To reduce tool cost, usually on low volume parts, by avoiding the need for a side movement within the tool which can add considerable cost to the tool price.

To produce a hole with greater strength.

When material flows around pins within an injection mould tool, the material fronts meet together and create a weld line.

Weld lines are weaker in strength than areas without weld lines and can, in some circumstances, reduce the strength to the point where it causes mechanical issues in use.